350um Fused Silica Wafer Quartz Borosilicate Glass Carrier Wafers

Product Details:

| Place of Origin: | China |

| Brand Name: | BonTek |

| Certification: | ISO:9001, ISO:14001 |

| Model Number: | Fused Silica, Fused Quartz |

Payment & Shipping Terms:

| Minimum Order Quantity: | 5 pcs |

|---|---|

| Price: | Negotiable |

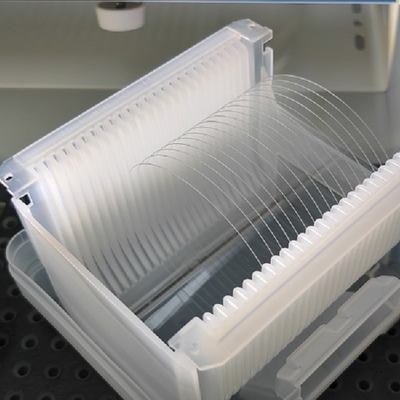

| Packaging Details: | Cassette/ Jar package, vaccum sealed |

| Delivery Time: | 1-4 weeks |

| Payment Terms: | T/T |

| Supply Ability: | 20000 pcs/Month |

|

Detail Information |

|||

| Material: | Glass Wafer | Type: | Fused Silica, Fused Quartz, Borosilicate, Soda Lime |

|---|---|---|---|

| Brand: | Corning, Schott, Ohara | Diameter: | 3'', 4'', 6'', 8'', 12'' |

| Thickness: | 350um, 500um, 1000um | Flat: | 22mm, 32.5mm, 47.5mm, 57.5mm |

| Surface: | DSP, SSP, DSL | Roughness: | Ra<1nm |

| Highlight: | Fused Silica Borosilicate Glass Wafer,Fused Silica Wafer 350um,Fused Silica Quartz Carrier Wafer |

||

Product Description

Fused Silica Quartz Borosilicate Glass Wafer As Carrier Wafers

Due to their low thickness, thin wafers are vulnerable to stress and breakage. Warping of the wafers during handling and processing causes a high yield loss or can even make it impossible to handle the wafers any more. This means that a thin wafer handling technology with a high degree of flexibility on wafer and substrate sizes is needed. Carrier wafers need to have certain properties, such as: mechanical robustness; chemical and high-temperature resistance; incredibly low tolerances (down to 1 μm thickness variation); and thermal expansion adjusted to the used material, for example, gallium arsenide (GaAs), Indium phosphide (InP), silicon (Si) or silicon carbide (SiC). Furthermore, handling tools sometimes need to be suitable for materials such as GaAs and Si, or even CMOS compatible.

High-end carrier wafers made of glass, quartz or silicon can meet the aforementioned requirements. Glass and quartz are excellent materials for carrier wafers because of their thermal stability and resistance against acids and other chemicals. Bonding to and de-bonding from glass and quartz carrier wafers can be monitored since they are transparent. Furthermore, glass carrier wafers can be cleaned and re-used, thus contributing to cost reduction and environmental protection.

BonTek works on a variety of glass and quartz materials, Fused Silica (JGS1, JGS2, JGS3, Corning 7980), Eagle XG, Schott BF33, Pyrex, MEMpax, B270, D263T, Zerodur etc.

![]()

![]()

![]()

|

Material |

UV Fused Silica, Fused Quartz (JGS1, JGS2, JGS3) |

||||||

|

Specification |

unit |

3” |

4” |

5" |

6" |

8" |

12" |

|

Diameter (or Square) |

mm |

76.2 |

100 |

125 |

150 |

200 |

300 |

|

Tol(±) |

mm |

<0.1~0.25 mm |

|||||

|

Thinnest Thickness |

mm |

>0.10 |

>0.10 |

>0.30 |

>0.30 |

>0.30 |

>0.50 |

|

Primary Flat |

mm |

22 |

32.5 |

42.5 |

57.5/notch |

notch |

notch |

|

LTV (5mmx5mm) |

µm |

<2 |

<2 |

<2 |

<2 |

<2 |

<10 |

|

TTV |

µm |

<8 |

<10 |

<15 |

<20 |

<30 |

<30 |

|

Bow |

µm |

±20 |

±25 |

±40 |

±40 |

±60 |

±60 |

|

Warp |

µm |

<30 |

<40 |

<50 |

<50 |

<60 |

<60 |

|

PLTV(<0.5um) |

% |

≥95%(5mm*5mm) |

|||||

|

Transmittance |

|

UV, Optical, IR or Custom option |

|||||

|

Edge Rounding |

mm |

Compliant with SEMI M1.2 Standard/refer to IEC62276 |

|||||

|

Surface Type |

|

Single Side Polished /Double Sides Polished |

|||||

|

Polished side Ra |

nm |

<1.0nm or specific per requested |

|||||

|

Back Side Criteria |

µm |

General is 0.2-0.5µm or as customized |

|||||

|

Appearance |

Contamination |

None |

|||||

|

Particles>0.3µm |

<=30 |

||||||

|

Saw Marks, striations |

None |

||||||

|

Scratch |

None |

||||||

|

Cracks, saw marks, stains |

None |

||||||

![]()

![]()

Acceptance Check

![]()

- The product is fragile. We have adequately packed it and labeled it fragile. We deliver through excellent domestic and international express companies to ensure transportation quality.

- After receiving the goods, please handle with care and check whether the outer carton is in good condition. Carefully open the outer carton and check whether the packing boxes are in alignment. Take a picture before you take them out.

- Please open the vacuum package in a clean room when the products are to be applied.

- If the products are found damaged during courier, please take a picture or record a video immediately. DO NOT take the damaged products out of the packaging box! Contact us immediately and we will solve the problem well.