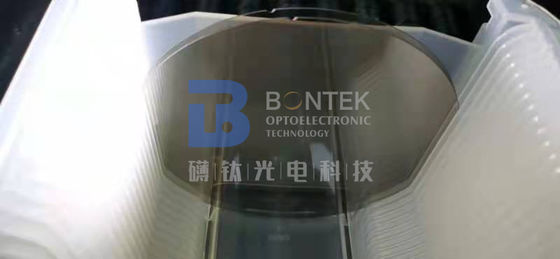

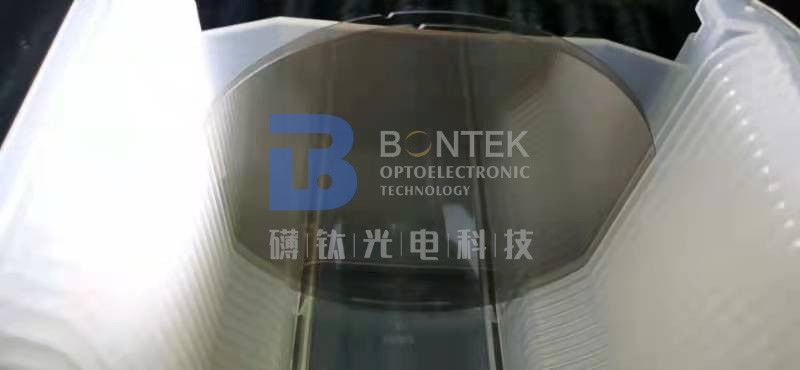

Single Crystal Lithium Tantalate Wafer LiTaO3 with Diameter Options 76 Millimeter 100 Millimeter and 150 Millimeter for Optical and Acoustic

Product Details:

| Place of Origin: | China |

| Brand Name: | CQT |

| Certification: | ISO:9001 |

| Model Number: | Lithium Tantalate (LiTaO3) |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 Pieces |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Cassette / Jar, put in a carton with PE foam. |

| Delivery Time: | 1-4 weeks |

| Payment Terms: | T/T |

| Supply Ability: | 10000 pieces/Month |

|

Detail Information |

|||

| Material: | Lithium Tantalate (LiTaO3) Crystal | Size: | 3'', 4'', 6'' |

|---|---|---|---|

| Cut Angle: | Y, Z, 28Y, 36Y, 42Y Etc. | Thickness: | 0.25mm, 0.35mm, 0.5mm, 1mm |

| Surface: | DSP, SSP, Lapping | Industry: | SAW Wafer, Optical Wafer |

| Highlight: | Single Crystal Lithium Tantalate Wafer for optical applications,LiTaO3 piezoelectric wafer with diameter options,Lithium Tantalate Wafer for acoustic devices |

||

Product Description

Single Crystal Lithium Tantalate Wafer LiTaO3 with Diameter Options 76 Millimeter 100 Millimeter and 150 Millimeter for Optical and Acoustic

For advanced applications in telecommunications, frequency control, and optoelectronics, our LiTaO₃ (Lithium Tantalate) Wafers offer unparalleled piezoelectric and electro-optic properties. Engineered for precision and reliability, these wafers are ideal for surface acoustic wave (SAW) devices, optical modulators, and high-frequency filters, where superior stability and low insertion loss are critical.

Crafted from single-crystal LiTaO₃, our wafers feature excellent temperature stability, high electromechanical coupling coefficients, and exceptional optical transparency (0.4–5 μm wavelength range). Their low dielectric loss and high Q-factor ensure minimal signal degradation, making them perfect for 5G infrastructure, RF communication systems, and laser technologies.

Available in custom orientations (e.g., X-cut, Y-cut, Z-cut), diameters, and thicknesses, our LiTaO₃ wafers are meticulously polished to meet stringent surface roughness and flatness specifications. Whether for research, prototyping, or high-volume production, our wafers deliver consistent, high-performance results.

Elevate your technology with the industry’s leading LiTaO₃ solution—choose our wafers for unmatched precision and reliability. Contact us today to discuss your requirements and secure a competitive edge!

Material Characteristics

| Material |

3" 4" 6" 8" LN wafer Saw/Optical grade |

3" 4" 6" LT wafer Saw/Optical grade |

| Orientation | X/ Z/ Y41°/ Y64°/ Y128°/ YZ/ YX or Customized | X112°/ Y28°/ Y36°/ Y42°/ YZ or Customized |

| Curie Temp | 1142°C±3°C | 605°C±3°C |

| Doped with | Zn, MgO, single or double doped available | Fe doped (Yellow Black) |

| Single Domain | Completed Polarization (White) / Reducted (Black) | |

Processing Capacity

| Surface finish | Single or Double side polish (DSL/SSP/DSP available) | |

| Thickness | 0.18/0.25/0.35/0.50/1.00 + mm | 0.25/0.35/0.50/1.00+mm |

| TTV | < 1~5µm | |

| BOW | ± (25µm ~40um ) | |

| Warp | <= 25µm | |

| LTV (5mmx5mm) | <1.5 um | |

| PLTV(<0.5um) | ≥98% (5mm*5mm) with 2mm edge excluded | |

| Edge | Compl't with SEMI M1.2@with GC800# .regular at C typed | |

| Orientation flats | Available, per request | |

| Polished side Ra | Roughness Ra<=5A | |

| Back Side Criteria | Roughness Ra:0.5-1.0µm GC#1000 | |

| Edge Rounding | Compliant with SEMI M1.2 Standard/refer to IEC62276 | |

| Cracks, saw marks, stains |

None |

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Acceptance Check

![]()

1. The product is fragile. We have adequately packed it and labeled it fragile. We deliver through excellent domestic and international express companies to ensure transportation quality.

2. After receiving the goods, please handle with care and check whether the outer carton is in good condition. Carefully open the outer carton and check whether the packing boxes are in alignment. Take a picture before you take them out.

3. Please open the vacuum package in a clean room when the products are to be applied.

4. If the products are found damaged during courier, please take a picture or record a video immediately. DO NOT take the damaged products out of the packaging box! Contact us immediately and we will solve the problem well.